If your signage looks great on day one but starts to wrap, fade, or delaminate by week three, there’s a material problem, not a design one.

And that’s exactly what many businesses are quietly battling. Whether you’re in retail, construction, exhibitions, or logistics, the quality of your signage printing board is just as critical as the message on it. You’re not looking for a solution that “just works” for now. You’re looking for one that works better, longer, stronger, and cleaner.

In this blog, we look at why choosing the right material matters more in 2025 than ever before. You’ll find a clear breakdown of two commonly compared materials: the traditional sunboard and the increasingly preferred honeycomb polypropylene board.

We’ll also walk you through Nilkamal BubbleGUARD’s PrintGUARD, designed for brands and businesses that simply expect more from their signage.

Understanding the Signage Materials

Before you choose the right signage printing board for your business, it’s important to understand what each material is built for and where it starts to fall short. While both sunboard and polypropylene boards serve the purpose of visual communication, their performance over time tells a very different story.

What is a Sunboard?

Sunboard, commonly referred to in the industry as PVC foam board, has been a standard signage medium for years. It's relatively easy to print on, lightweight, and gives a decent finish. It's widely used in retail displays, indoor advertising, and promotional panels.

However, sunboards are prone to warping under prolonged exposure, and the foam core makes them susceptible to breakage and denting. Moreover, recyclability is limited, an increasing concern in environmentally conscious sectors.

What is a Honeycomb Plastic Sheet and Why Businesses Prefer It

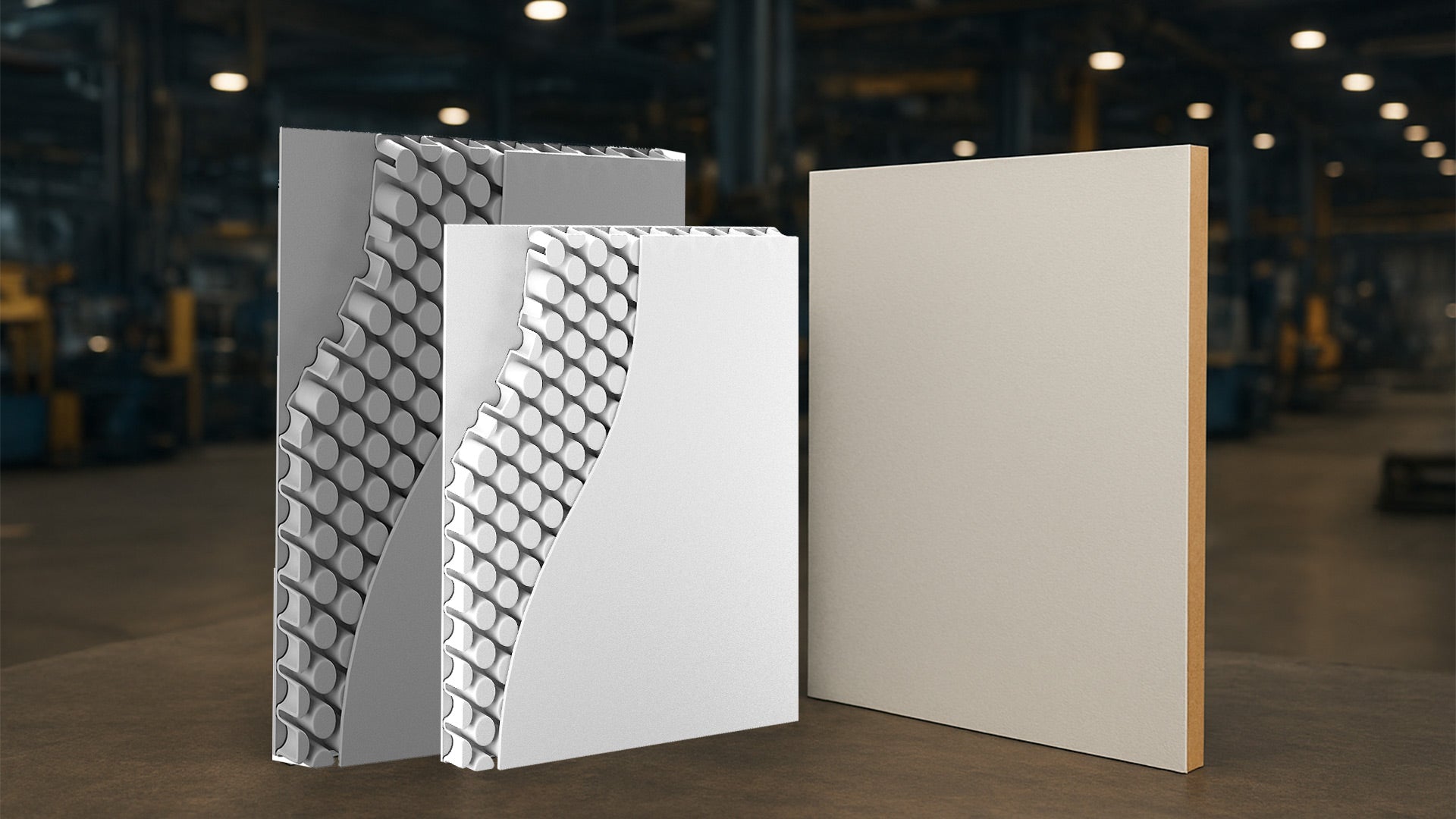

A honeycomb plastic sheet made from polypropylene is engineered differently. At its core, quite literally, is a network of circular or hexagonal air pockets that provide uniform strength and structural rigidity.

Unlike conventional foam boards, polypropylene boards are non-absorbent, highly resistant to impact, and offer better dimensional stability. Their recyclability makes them a responsible choice for forward-thinking businesses that don’t want performance at the cost of the planet.

Why the Shift Towards Polypropylene Boards?

When signage is being installed in high-traffic zones, public places, construction sites, or warehouses, two priorities come up repeatedly: durability and print clarity.

Here’s where polypropylene boards begin to outshine their conventional counterparts:

1. Long-Term Flatness and Stability

Sunboards often develop curves or waves over time, especially in non-climate-controlled environments. Polypropylene boards, particularly those with a honeycomb structure, remain flat even when subjected to changing temperatures or humidity.

2. Better Impact Resistance

In dynamic environments like construction zones or manufacturing units, boards are often knocked around. Polypropylene offers higher resistance to dents and breakage, thanks to the structure of the honeycomb plastic sheet.

3. Cleaner Finish for Branding

Especially in B2B signage, presentation isn’t secondary, it sells. A polypropylene board offers a cleaner, matte finish with excellent ink adhesion. It also resists scratches and scuffs better than a foam-core sunboard.

4. Environmentally Responsible

With more tenders, contracts, and partnerships now prioritizing sustainability, choosing a 100% recyclable signage printing board becomes a strategic move, not just an ethical one.

Introducing PrintGUARD by Nilkamal BubbleGUARD

Nilkamal’s answer to the above demands is PrintGUARD, a next-gen polypropylene board designed to address every shortcoming of traditional signage materials.

What sets PrintGUARD apart isn’t just its construction. It’s how deeply it understands the use-cases it’s meant for. Developed specifically for the signage and display industry, PrintGUARD combines performance and sustainability into one precision-engineered product.

Why PrintGUARD is Becoming the Preferred Sunboard Alternative in 2025

As more industries move toward smarter material choices, PrintGUARD is fast becoming the preferred sunboard alternative. Its thoughtful engineering and consistent performance address the real, everyday challenges that conventional signage materials often fall short on. Below are some of its key benefits to look at:

-

Completely Flat Surface: PrintGUARD’s circular honeycomb core creates a stable, uniform surface for seamless printing. No bulging. No warping.

-

High Rigidity Without Added Bulk: The lightweight design doesn’t compromise stiffness. That means easier installation without structural flex.

-

Consistent Print Quality: Thanks to the corona treatment on its surface, inks adhere better and visuals appear sharper. This ensures branding stays crisp from day one to day ninety.

-

Versatility Across Cutting Methods: Whether you use CNC, laser, or manual cutting, PrintGUARD handles all with ease, allowing for efficient custom shapes without frayed edges.

-

Compatible With Thermoforming and Welding: Unlike traditional boards that crack under thermal processes, PrintGUARD adapts. Fabricated signage or modular displays can be constructed more seamlessly.

-

Equal Strength in All Directions: This feature is vital for freestanding installations or suspended signage. No weak sides, literally.

-

Fully Recyclable: Made from virgin polypropylene, it aligns with companies aiming for zero-waste or low-carbon footprint operations.

The Signage Challenge in 2025

Today, businesses aren’t just seeking signage that “looks good.” They need it to last, adapt, and align with evolving regulations and sustainability mandates. Industries like automotive, warehousing, FMCG, and infrastructure are demanding higher performance from every material they invest in, including signage.

That’s where Nilkamal BubbleGUARD’s technology steps in. It doesn’t merely replace older materials; it redefines what businesses should expect from them.

PrintGUARD isn’t just a polypropylene board. It’s a carefully developed solution for enterprises who need professional signage that doesn’t bend under pressure, literally or figuratively.

Making the Smarter Choice for Your Signage Printing Board

If you’ve been defaulting to sunboard out of habit, it might be time to reconsider. While it once served well, the demands of modern industries, branding standards, and environmental responsibilities have shifted.

Honeycomb polypropylene boards, and specifically PrintGUARD, are not just alternatives, they’re upgrades. By using them, the company will reduce the number of replacements, printing-related problems, support the brand image, as well as facilitate the evolution of sustainable business.

The Verdict

In short, the type of material you use is not simply a technical aspect of creating signage; it is a strategic choice. Durability and quality are nonnegotiable, whether you are establishing a retail chain, overseeing large-format prints, or installing events on a rollout basis.

Sunboards could still be circulating in the market, but the increased need for consistency, resilience and sustainability has changed the preference. More companies are shifting towards materials that not only cover short-term solutions but also long-term plans.

Nilkamal BubbleGUARD’s PrintGUARD brings that advantage to the table, offering not just superior print results but a smarter, more dependable way to approach signage for today’s business needs.