The versatile solution for printing, protection and packaging

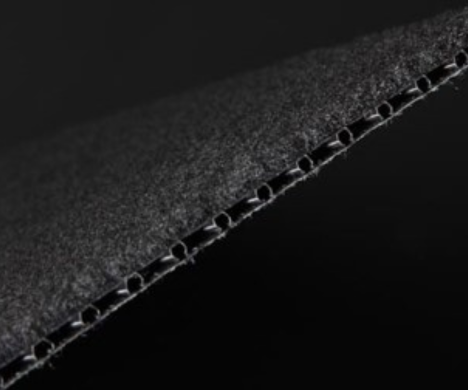

Nilkamal BubbleGUARD is a revolutionary material designed todeliver unmatched protection, durability, and versatility. Engineered with a patented multilayer structure, it features a central bubble core sandwiched between two flat layers. This unique construction ensures lightweight strength, impact resistance, and cushioning, making it ideal for protective applications across industries. From industrial packaging for automotive, steel, glass or technical materials, BubbleGUARD stands out as a superior alternative to conventional materials due to its long-lasting durability, versatility and recyclability.

Highly Durable

Uniform Strength

Highly Reusable

Quality Tested

Lightweight

100 % Recyclable

Product Range

Versatile Solutions

Case Studies

View All

A simple upgrade saved 21 Cr per year

A leading paint manufacturer from India switched from traditional plywood based sheet separators to Nilkamal SheetGUARD and has saved 21 Cr in one year for one location. The solution is Designed to be re-used multiple times - Guaranteed 70 Cycles as opposed to max of 5 cycles that the traditional ply based interlayer sheets were offering. SheetGUARD is safe and easy to use as paint cans of 20 Liters easily slide on BG surface hence works need to apply very less human force.

Enhancing Product Safety with Reusable PackGUARD Boxes

Our client, a leading furniture rental brand, previously facing significant product damage (TVs, refrigerators, washing machines, ovens) due to inadequate packaging, made a fresh investment in protective solutions with Nilkamal BubbleGUARD. The products they rent are high value and to ensure maximum safety, we proposed customised 1200 GSM reusable PackGUARD boxes for various appliances, including refrigerators, LED TV units, microwaves, and air conditioners, washing machines. The client now enjoys more reliable protection, with the added bonus of sustainability through reusable packaging.

Minimising damage and maximising durability with YarnGUARD

A leading synthetic yarn manufacturer faced significant challenges with paper-based interlayer separator sheets, as moisture absorption during the dyeing process caused yarn damage. Flute boards as high as 1850 GSM PP failed tests. Nilkamal BubbleGUARD provided a game-changing solution that matched the weight-carrying capacity, offered enhanced durability and eliminated moisture absorption issues and that too at 1300 GSM. The result: cost-effective, optimized material with superior quality, ensuring safe and efficient yarn processing.

Optimized Packaging Solutions for beverages

Nilkamal SheetGUARD helped standardise and organise the packaging for india’s largest packaged drinking water company. The high-quality interlayer sheets ensure superior product protection during storage and transport. With highly organized storage and reduced usage costs, SheetGUARD delivers efficient, cost-effective solutions for businesses.

Reusable packaging for maximised efficiency

By replacing traditional thermocol (EPS) sheets with customized SheetGUARD interlayer sheets, the client achieved enhanced durability, reusability, and operational efficiency in their in-plant processes, significantly reducing packaging waste and maintenance costs.

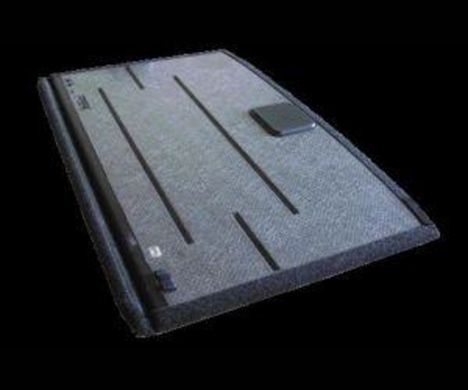

Revolutionizing Automotive Interiors with Advanced Luggage Carpet Covers

This customized automotive luggage carpet cover offers high strength, durability, and lightweight design while ensuring lasting performance. Being made with 100% virgin polypropylene this application is waterproof, termite and bacteria-proof, energy-efficient, and provides excellent thermal insulation, all while enhancing aesthetics for a leading Indian car manufacturer.

Revolutionizing Beverage Packaging with a Weatherproof, Reusable Solution

A leading beverage company, faced persistent packaging challenges due to their open-air storage facility. Traditional paper corrugated sheets absorbed moisture, leading to structural failure, bottle breakage, and increased waste. Nilkamal BubbleGUARD introduced a customised solution with SheetGUARD, a weatherproof and reusable solution that withstood temperature extremes, enhanced product safety, and minimized breakage. The customised durable interlayer trays reduced strapping needs and provided long-term reusability, eliminating scrap and optimizing costs.

A simple upgrade saved 21 Cr per year

A leading paint manufacturer from India switched from traditional plywood based sheet separators to Nilkamal SheetGUARD and has saved 21 Cr in one year for one location. The solution is Designed to be re-used multiple times - Guaranteed 70 Cycles as opposed to max of 5 cycles that the traditional ply based interlayer sheets were offering. SheetGUARD is safe and easy to use as paint cans of 20 Liters easily slide on BG surface hence works need to apply very less human force.

Enhancing Product Safety with Reusable PackGUARD Boxes

Our client, a leading furniture rental brand, previously facing significant product damage (TVs, refrigerators, washing machines, ovens) due to inadequate packaging, made a fresh investment in protective solutions with Nilkamal BubbleGUARD. The products they rent are high value and to ensure maximum safety, we proposed customised 1200 GSM reusable PackGUARD boxes for various appliances, including refrigerators, LED TV units, microwaves, and air conditioners, washing machines. The client now enjoys more reliable protection, with the added bonus of sustainability through reusable packaging.

Minimising damage and maximising durability with YarnGUARD

A leading synthetic yarn manufacturer faced significant challenges with paper-based interlayer separator sheets, as moisture absorption during the dyeing process caused yarn damage. Flute boards as high as 1850 GSM PP failed tests. Nilkamal BubbleGUARD provided a game-changing solution that matched the weight-carrying capacity, offered enhanced durability and eliminated moisture absorption issues and that too at 1300 GSM. The result: cost-effective, optimized material with superior quality, ensuring safe and efficient yarn processing.

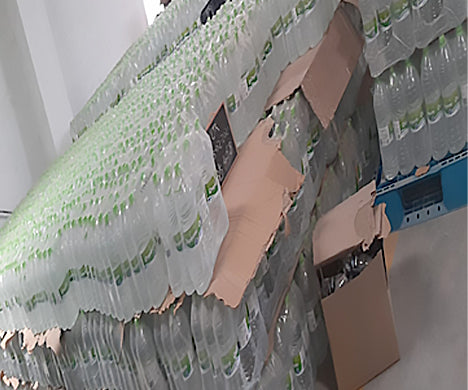

Optimized Packaging Solutions for beverages

Nilkamal SheetGUARD helped standardise and organise the packaging for india’s largest packaged drinking water company. The high-quality interlayer sheets ensure superior product protection during storage and transport. With highly organized storage and reduced usage costs, SheetGUARD delivers efficient, cost-effective solutions for businesses.

Reusable packaging for maximised efficiency

By replacing traditional thermocol (EPS) sheets with customized SheetGUARD interlayer sheets, the client achieved enhanced durability, reusability, and operational efficiency in their in-plant processes, significantly reducing packaging waste and maintenance costs.

Revolutionizing Automotive Interiors with Advanced Luggage Carpet Covers

This customized automotive luggage carpet cover offers high strength, durability, and lightweight design while ensuring lasting performance. Being made with 100% virgin polypropylene this application is waterproof, termite and bacteria-proof, energy-efficient, and provides excellent thermal insulation, all while enhancing aesthetics for a leading Indian car manufacturer.

Revolutionizing Beverage Packaging with a Weatherproof, Reusable Solution

A leading beverage company, faced persistent packaging challenges due to their open-air storage facility. Traditional paper corrugated sheets absorbed moisture, leading to structural failure, bottle breakage, and increased waste. Nilkamal BubbleGUARD introduced a customised solution with SheetGUARD, a weatherproof and reusable solution that withstood temperature extremes, enhanced product safety, and minimized breakage. The customised durable interlayer trays reduced strapping needs and provided long-term reusability, eliminating scrap and optimizing costs.

Connect with an expert

Fill the details below and we will contact you regarding your enquiry

Thank you

We have received your enquiry and will respond to you within 24-48 business hours.