If you're managing materials, transport, or packaging in today's supply chain, you're probably already familiar with the growing pressure to reduce waste, protect goods, and recover value fast. And that pressure doesn’t end when a product reaches its destination. In fact, that’s often when the real work begins.

Reverse logistics is no longer a back-office task. It’s a critical part of how modern supply chains stay efficient, cost-effective, and environmentally responsible.

At Nilkamal BubbleGUARD, we work closely with businesses across sectors to strengthen their reverse systems, from durable interlayer sheets to returnable industrial packaging solutions that make repeat cycles viable and smooth.

This blog unpacks the value of reverse logistics and how purpose-built packaging can directly support a better, more resilient supply chain.

What Exactly Is Reverse Logistics?

Reverse logistics is the process of moving goods, materials, or packaging backward through the supply chain. This could mean retrieving empty containers, collecting reusable interlayers, or returning damaged goods for repair or recycling.

In practice, it includes:

-

Handling customer or dealer returns

-

Transporting packaging materials back for reuse

-

Recycling obsolete or surplus inventory

-

Refurbishing or repackaging items for secondary use

What often gets overlooked is how dependent this process is on the quality and durability

of materials involved. If packaging fails on the return trip, the whole system suffers, both operationally and financially.

Why Reverse Logistics Matters for Supply Chain Efficiency

Reverse logistics has quietly become one of the most strategic moves in modern supply chains, playing a critical role in improving supply chain efficiency, reducing waste, and reclaiming value across operations.

Here’s why:

1. Cost Pressure Is Relentless

Every returned product or reused packaging item saves procurement and manufacturing costs. But only if it arrives back intact.

That’s where SheetGUARD comes in. These high-rigidity interlayer separator sheets are designed with a unique honeycomb structure that makes them tough enough for repeated handling. Lightweight yet strong, they help businesses cut down on material replacement cycles.

2. Returnable Packaging Is a Competitive Advantage

Reusable packaging isn’t just better for the environment. It gives you tighter control over inventory, reduces breakage in transit, and supports leaner logistics.

PackGUARD, our customisable industrial carton solutions, helps businesses shift from disposable corrugated boxes to a returnable system that’s stronger, smarter, and scalable. Whether it’s adding partitions or integrating locks and handles, these packaging units are built for the long haul and the return trip.

3. Regulatory and ESG Goals Are Driving Change

Reverse logistics directly supports sustainability targets. The ability to reuse and recycle materials across cycles means fewer raw materials consumed and less landfill waste.

Our YarnGUARD boards, built from 100% recyclable virgin polypropylene, are purpose-designed for textile transport. They hold their form under pressure, resist moisture, and eliminate the need for single-use plastic interlayers in demanding storage conditions.

The Reverse Supply Chain: Where Smart Systems Begin

There’s a growing recognition that reverse logistics isn’t just a backup plan, it’s part of a circular system that, when designed well, creates measurable efficiencies.

But for that to work, packaging needs to hold up.

Here’s what strong reverse logistics looks like in practice:

-

Standardised packaging materials that can be tracked, reused, and stored easily

-

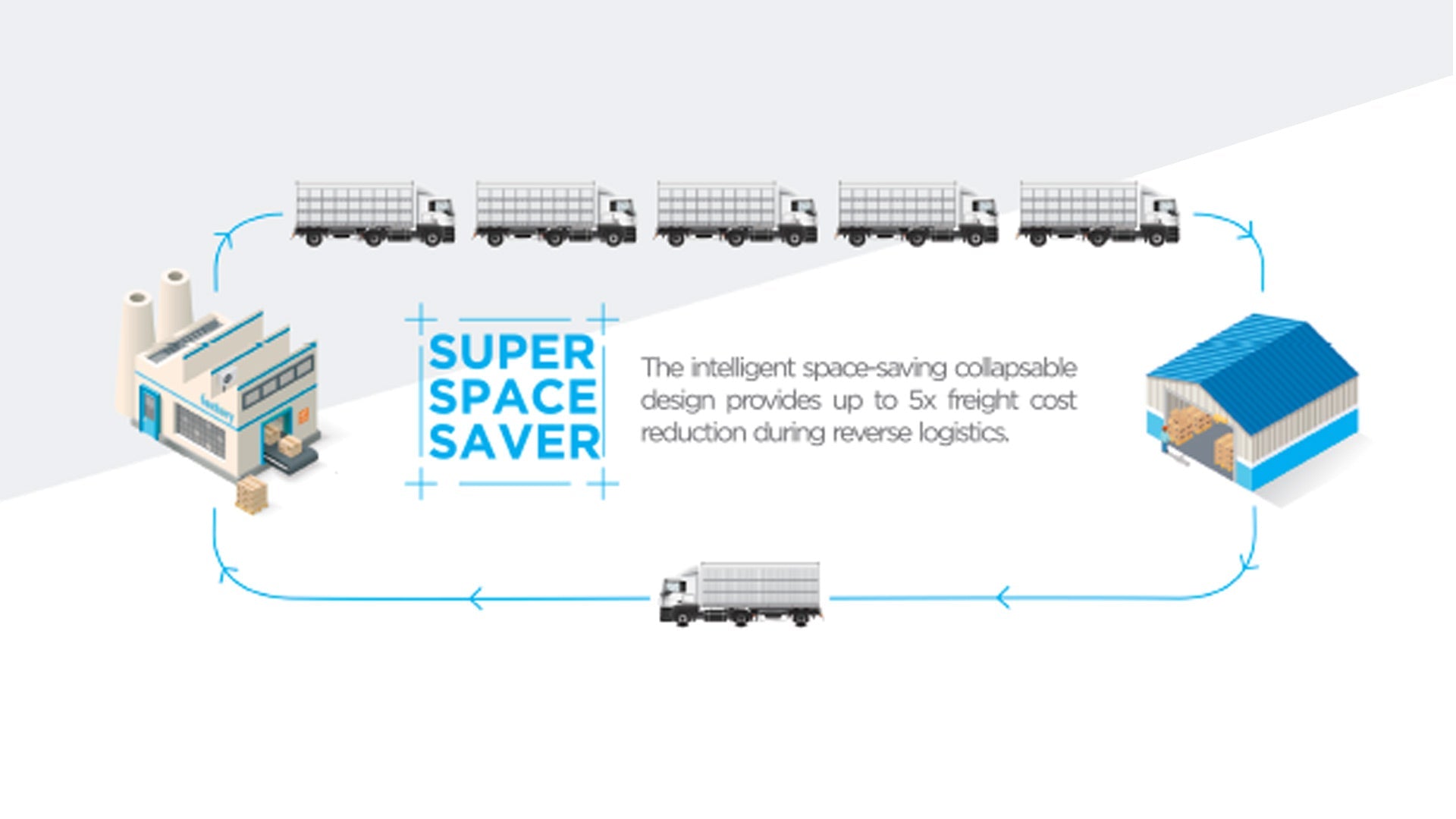

Lightweight boards that reduce freight costs on the return journey

-

Custom-fit packaging that minimizes empty space and improves load density

-

High load-bearing capacity, even at lower GSM, ensuring safety in handling and stacking

Nilkamal BubbleGUARD products check all these boxes; while offering complete recyclability and ease of fabrication.

Common Reverse Logistics Pitfalls and How to Solve Them

Reverse logistics adds immense value, but it also brings its own set of challenges. From packaging failures to high return costs, these hurdles can slow down even the most well-planned operations.

Here are a few common issues businesses run into, and how Nilkamal BubbleGUARD solutions are built to overcome them:

-

Challenge: Materials degrade too quickly during reuse

-

Solution: Our patented air-lock honeycomb structure gives each board the strength to withstand multiple cycles. This includes everything from stacking loads to repeated interplant transfers.

-

Challenge:High return costs offset reuse benefits

-

Solution: Lightweight materials reduce transportation weight and cost. Both SheetGUARD and PackGUARD help cut freight charges without compromising durability.

-

Challenge:Inconsistent dimensions slow down handling

-

Solution: Every product we offer, from flat interlayers to fabricated storage boxes is available in custom sizes and designs, including rounded edges and screen-print branding.

These optimisations not only reduce friction but also add predictability to your reverse supply chain.

Smarter Packaging Drives a Resilient Reverse Supply Chain

Still treating packaging as a one-time cost? That mindset can lead to ongoing operational losses.

Choosing robust, returnable packaging not only improves the reverse journey but it brings long-term value. A well-executed reverse supply chain turns return logistics into a driver of cost savings, process efficiency, and environmental responsibility.

By investing in materials that last longer, return cleaner, and recycle easier, you're creating systems that are built to sustain, not just survive in today’s logistics demands.

Why Nilkamal BubbleGUARD Packaging Works for Reverse Logistics

At Nilkamal BubbleGUARD, we don’t just design packaging like everyone else does; we engineer solutions that perform at every stage of your supply chain, including the crucial return journey.

With SheetGUARD, PackGUARD, and YarnGUARD, businesses gain:

-

Lightweight construction for lower freight cost

-

High stiffness and point-load resistance

-

Flat surfaces for ease of stacking and storage

-

Reusability across multiple handling cycles

-

Full customisation in dimensions, color, and branding

-

Complete recyclability for end-of-life sustainability

In other words, you're not just buying packaging. You’re investing in a smoother, more resilient flow of materials both forward and backward.

Reverse logistics has evolved far beyond handling returns; it's now a key driver of circular, efficient, and future-ready supply chains.

At Nilkamal BubbleGUARD, every product is thoughtfully engineered to support this shift, layer by layer. Whether you’re upgrading your packaging strategy or building a more sustainable logistics loop, our solutions are built to go the distance and come back ready for more.