The industrial packaging sector is going through a lot of changes in 2025. Firms in manufacturing, automotive, food and chemical industries are interested in solutions that combine endurance, sustainability and affordability.

Shifts in how products trade worldwide and new regulations are causing the market to move quickly.

Now, let’s examine the size of the industrial packaging 2025 market, the latest patterns influencing it and recently introduced designs that help meet the needs arising from these trends.

Market Size and Outlook for 2025

The industrial packaging industry is steadily expanding, as it is predicted to keep growing for the next few years. As demand grows across various fields, experts predict that the market value will go up significantly.

That expansion is made possible by a CAGR of 4.6% over the period, demonstrating the industry’s versatility and durability.

According to McKinsey “tomorrow’s packaging will be smart, personalised, and reusable.” This is important because it signals the main reasons for the industry’s growth in future market expansion.

Key drivers behind this growth include:

-

More manufacturing and construction are taking place, mainly in developing countries.

-

Increasingly, people require safe and smooth ways to move and store large and sensitive items.

-

As e-commerce and international trade increase, it has become necessary to use packaging that will endure long journeys.

-

Heightened focus on regulatory compliance and product safety.

Since industries are expanding and supply chains are becoming more complex, packages must adjust accordingly.

Industrial Packaging Market Growth: What’s Fueling the Expansion?

Several different trends are fueling the growth of the industrial packaging market. Nowadays, the industry is focused on adding worth and improving all phases of logistics processes.

What’s driving the industrial packaging market growth?

-

Customisation: Companies now want packaging made especially for their products, including automotive and pharmaceutical items.

-

Durability and Reusability: Materials now being used are chosen for their ability to last and be used over and over, as this helps save resources and money.

-

Efficiency: Shipping expenses are kept low, while goods remain strong, because of lightweight materials.

-

Sustainability: Recyclable and reusable packaging is being requested more often because companies aim to minimise the effects they have on nature.

What Trends Will Influence Industrial Packaging in 2025

A number of trends are driving the growth of industrial packaging. Businesses are moving forward with changes in green, smart and flexible solutions based on expected market demands.

Key trends include:

-

Sustainable Materials: Using recycled plastics, biodegradable polymers, and reusable systems is becoming more popular in the industry. Many companies are now choosing packaging that can be used many times, helping to support the circular economy.

-

Packaging Technology: Increasingly, sensors and monitors are used in packaging to keep track of temperature and humidity, so that goods stay safe while moving to their destination.

-

Modular and Stackable Designs: Having products packed into stacks that can still be reused for storage is becoming fashionable, leading to greater use of space and benefits.

-

AI and Data Analytics: Artificial intelligence is applied to modern packaging and logistics systems to lower the amount of material used and help operations run more effectively.

These industrial packaging trends are changing how goods are protected, moved and kept safe, which supports businesses with improved opportunities for smoother operations and meeting environmental goals.

Industrial Packaging CAGR: Measuring the Momentum

The industrial packaging CAGR demonstrates how strong and active this sector really is. According to Coherent Market insights: The industry is expected to improve by an annual compound growth rate of more than 5.4% from 2025 to 2032. The rise is most evident in rapidly industrialising areas like the Asia-Pacific and in sectors where strong packaging is key, such as chemicals, construction and automotive.

Nilkamal’s Smart Solutions for Industrial Packaging 2025

As industrial packaging heads toward 2025, Nilkamal BubbleGUARD continues to lead with smart, durable, and sustainable industrial packaging solutions tailored to the evolving needs of the market.

SheetGUARD

With a special air-locked honeycomb system, SheetGUARD provides reusable and strong interlayer and separator sheets for packaging returned by customers. Lightweight yet rigid, they are ideal for sectors like automotive, glass, and bottling.

Key Highlights:

-

Excellent load-bearing strength

-

Lightweight and cost-efficient

-

Custom sizes and branding

-

100% recyclable

PackGUARD

PackGUARD boards and storage boxes made with polypropylene are designed for industrial use and still show strength and resistance even when the GSM is not that high. Fully customizable, they’re ideal for long-term storage and returnable systems.

Key Highlights:

-

Superior durability and impact resistance

-

Liquid-proof and reusable

-

Custom dimensions with added features (locks, handles, etc.)

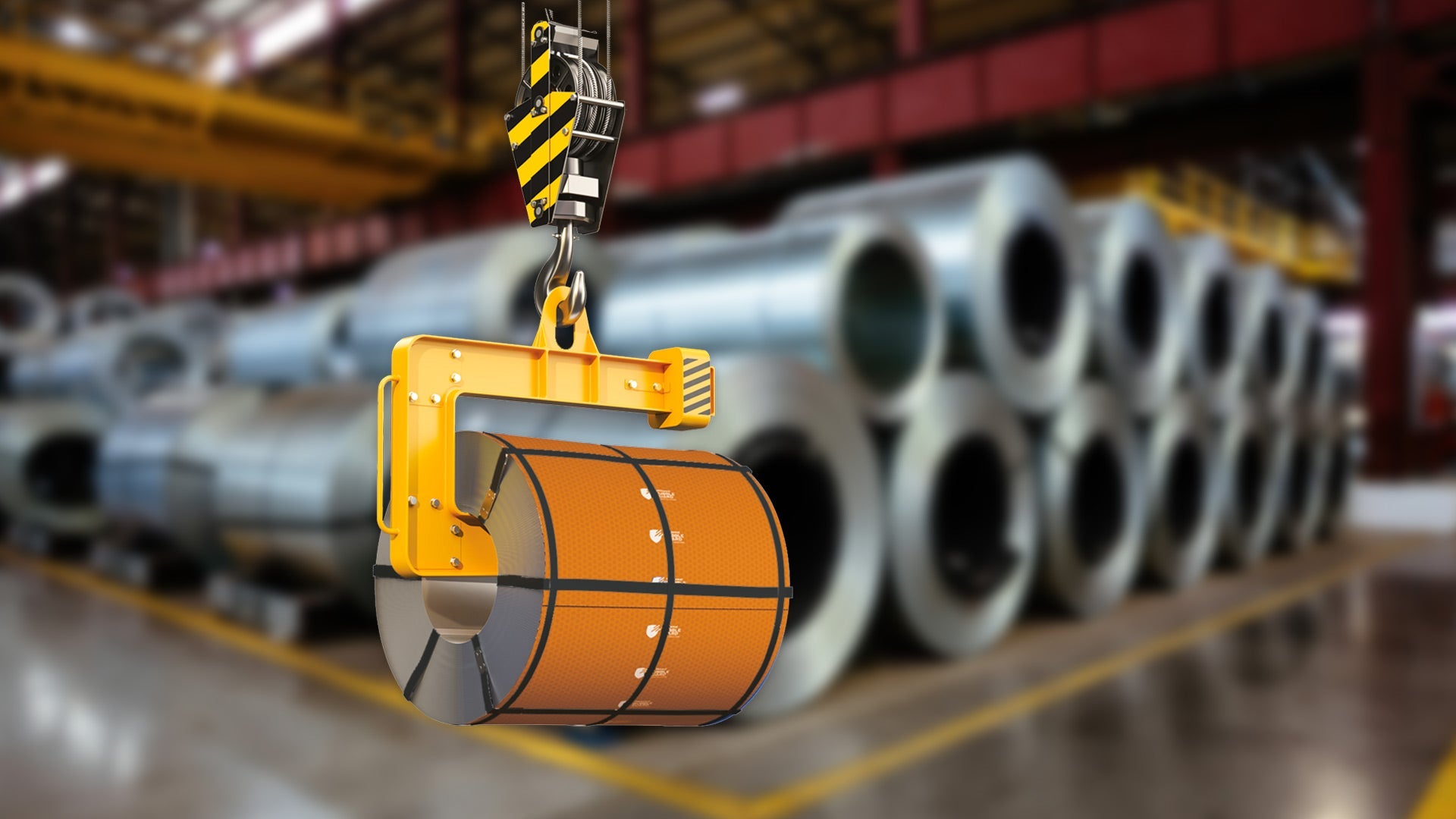

CoilGUARD

Designed for metal and cable coils, CoilGUARD uses patented honeycomb tech for advanced cushioning. Made from recyclable polypropylene, these sheets are very lightweight and easy to wrap.

Key Highlights:

-

Flexible, secure coil protection

-

Quick to apply and reduces damage risk

-

Sustainable and recyclable

Nilkamal’s innovative product range is built to meet the future of industrial packaging— efficient, eco-conscious, and ready for change.

The industrial packaging sector in 2025 will be defined by quick development, innovative approaches and increased focus on sustainability. When industries evolve, their packaging does too; now we require packaging that is sturdy, efficient and environmentally friendly. Working with the latest technology, Nilkamal helps solve these issues by making the industry safer, more efficient and friendlier to the environment, steering towards a better and more responsible future.